Building on Jetting Success

John Jones – Water Jetting Association

Growing awareness of the benefits of water jetting skills development is a Middle East success story – now is the time to build on progress, says the Water Jetting Association, the UK member body for the industry.

Across the Middle East, there are growing centres of water jetting excellence. Practice is up there with the best in the world, certainly the best in the United Kingdom. Businesses are embracing the need for effective skills development.

While there is always more to be done to improve safety and operational performance, this is an ongoing success story that has been building over many years, and one that should be celebrated.

WJA Registered Examination Bodies and WJA Approved Coach/Examiners have delivered Water Jetting Association (WJA) courses in the Middle East for 30 years or more.

Uniformly noticeable is how operatives eagerly welcome the chance to develop and test their skills. Also, how the awareness of the advantages of water jetting training has grown steadily among operations managers.

Controls are critical

The case for water jetting skills development is clear, and we want to see this success continue.

Water jetting is critical to many key industries in the region, notably gas and oil exploration and production, petrochemical refineries, maritime engineering, dockyards, shipping, multiple industrial applications, and municipal works.

Without water jetting, heat exchangers would rapidly clog and become unusable and municipal drains and sewers could not be effectively cleaned.

Water jetting is vital for cleaning holding tanks, process vessels and production pipes across many industrial sectors. It is used to defoul the hulls of ships, and remove layers of paint and coatings, ready for new ones to be applied.

However, the nub of the issue is that water jetting is extremely hazardous, and without the appropriate controls in place can lead to devastating injuries and fatalities.

A jet of water of 7 bar of pressure (100 psi) can penetrate human skin and membranes. Under NACE (National Association of Corrosion Engineers) Standards that the WJA follows, high pressure water jetting rises to 1,700 bar (24,650 psi), while ultra-high water jetting is classed as pressures above 1700 bar (24,6500 psi). Many contractors commonly use pressures up to 2,750 bar or 40,000 psi.

Supersonic jets

At higher pressures, water jets can leave the jetting nozzle at over twice the speed of sound. The devastation such power can cause the human body is immense and can be fatal. This is why health and safety must be at the heart of all water jetting training.

It has certainly been the prime concern of the WJA, since it was founded as the world’s first trade body for the water jetting industry in the UK in 1980. From day one we have had clear goals:

· Set clear standards for the water jetting industry;

· Provide the means to achieve those standards, notably through effective coaching and examining;

· Work with stakeholders to continuously update our standards, assessments and industry support in line with changing technologies and applications.

Strengthening standards

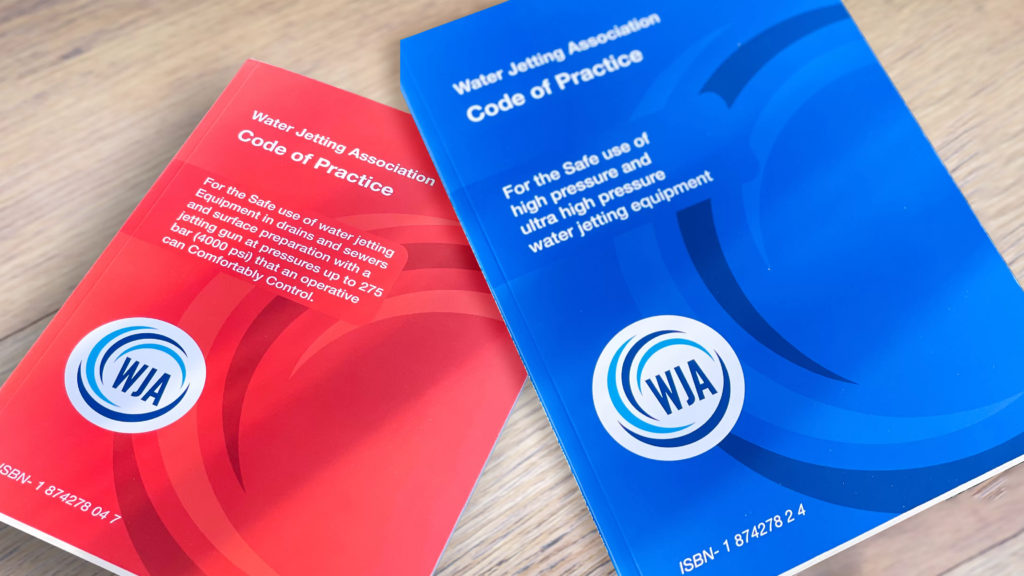

Our codes of practice define the WJA’s standards.

These are the Blue Code, for the safe use of high pressure and ultra-high pressure water jetting equipment, and the Red Code, for the safe use of water jetting equipment in drains and sewers and surface preparation with a jetting gun at pressures up to 275 bar (4,000 psi) that an operative can comfortably hold.

Both have been extensively updated in 2023. A new Purple Code, for the use of pressure washing equipment, is due to be published by the end of 2023.

For the marine and dockyards and the oil, gas and petrochemical industries in the Middle East, the Blue Code is of primary interest. The code of practice covers all key issues related to high and ultra-high pressure jetting, including:

- Water jetting teams – organisation and duties;

- Site set-up;

- Water jetting units;

- Hose assemblies – inspection and testing;

- Safe use of water jetting equipment;

- Jetting equipment maintenance;

- Injuries and ill-health;

- Response to injury.

This year’s revisions have been made in consultation with members and industry stakeholders, notably the HSE, the UK’s national health and safety agency.

A key aim has been to strengthen water jetting standards and guidance needed to achieve them. There are many instances where, previously, the code stated an action ‘should’ be taken now states that it ‘shall be’ taken.

It is good to know that many water jetting service users in the Middle East consider the WJA’s Blue Code to be the expected standard to work to. So, we hope these changes will be welcomed by specifiers, health and safety professionals and operational teams in the region.

Theory and practice

The WJA’s codes of practice determine and underpin the content of our water jetting coaching and examination programme. All courses, which we call WJA events, in the programme are accredited by City & Guilds in the UK.

A key concern is to combine theoretical knowledge with practical skills. This is achieved by pairing two types of WJA event. The first is Safety Awareness, a one-day class-based event that introduces candidates to key water jetting concepts and the vital necessity for carrying out jetting tasks safely.

Once operatives have passed this, they must also take at least one of five WJA practical modules – Tube and Pipe, Surface Preparation, Hydrodemolition, Drain and Sewer, or Drain, Sewer and Surface Preparation – which each one normally takes a day to complete.

These practical modules combine class-based coaching with practical assessments, giving operative candidates hands-on experience, under instruction, of using water jetting equipment.

It also gives the WJA Coach/Examiner the opportunity to see that concepts covered in class learning are being put into practice.

Candidates that pass both WJA events are placed on our international database of water jetting operatives. They also receive a personal WJA jetting card.

Their status as WJA certified water jetting operatives can then be maintained by attending and passing a Safety Awareness Refresher event every three years.

The WJA also offers a one-day City & Guilds accredited Pressure Washing course. This covers all aspects of using water jetting units operating up to 207 bar (3,000 psi) and a flow rate up to 22 litres per minute, with class-based coaching and a practical assessment.

Digital future

For all these events, candidates undergo a formal examination. Until 2023, that has been achieved with an end-of-course written test, with 20 questions and a 75% pass mark.

The WJA is now moving over to a digital examination system, using the CLiKAPAD digital question and answer tool.

Candidates are given blocks of multiple choice questions, throughout the event, which they answer by clicking wireless pads. Their responses cannot be changed, but they are seen by the examiner, who can assess whether learning points need to be reviewed. Again, there is a 75% pass mark.

There are some key advantages with this new digital system, which is receiving excellent feedback. It also helps people with reading and writing difficulties.

The questions and answers can be read out by the WJA coach/examiner, or the interpreter. It also makes the coaching more engaging and less intimidating, with assessment carried out throughout the course.

Digital assessment is also aligned with another big drive in WJA training, which is an ongoing process to digitise the issuing of certificates and providing a digital record of every operatives’ training status.

This process has already generated significant sustainability benefits. The carbon footprint of our examination programme has shrunk significantly. Employers and operatives also receive examination results more quickly.

Digitisation is also making examination verification more robust. Both employers and service users can instantly check an operative’s current examination status on a digital portal which is accessed by clicking on a QR code on the operative’s WJA card and certificate.

Going global

At the start of this article, I stated that centres of excellence in water jetting are developing across the Middle East, and that this is a cause for celebration.

However, the WJA is not standing still. Until now, all WJA events have been led, in accordance with our constitution, by WJA Approved

Coach/Examiners who are based in the UK. In 2023, though, we changed the rules.

From now on, training bodies based anywhere in the world can apply to become WJA Registered Examination Bodies, working with WJA Approved Coach/Examiners also based in their own regions.

Our hope is that this will help keep up with demand for City & Guilds accredited WJA coaching events and examination. It is the natural next step to promote internationally respected standards.

We hope that means we’ll receive applications from the exceptional training bodies in the Middle East, including the United Arab Emirates, Saudia Arabia and Kuwait.

We have clear procedures to support non-UK applications. The standards expected are the same as those we set for UK-based examination partners. If non-UK training bodies meet the application criteria, we would be very pleased to work with them.

Impressive progress

Given the international nature of workforces in major industries in the Middle East, notably oil and gas exploration, petrochemicals, marine and dockyards, training bodies based in the region will face similar challenges to UK-based colleagues, minus the long flights.

Steve Williams, the WJA’s Training and Safety Chairman, regularly delivers coaching in the Middle East. He is impressed with the progress on standards and the enthusiasm of candidates.

“In some areas, water jetting standards are as high as in Europe,” he says. “Equipment auditing is strong, which results in water jetting equipment being kept in good condition. That includes hoses, which is essential.

“All operatives I coach use the latest and best water jetting PPE. There is also a real hunger for WJA coaching and examination.

“Language can be a problem. But this can be overcome by having a senior member of the team, usually a foreman, who can speak English, as an interpreter. They must be technically proficient to explain the concepts properly.”

There is a strong focus in the region on using automated and semi-automated systems, for example, in both the marine industry and in tube bundle cleaning.

“The main imperative is, perhaps, to exploit productivity benefits,” says Steve Williams. “But it’s also a big positive for safety because the

operative is moved away from the jet and, therefore, any potential hazards.”

Dockyards have been using ultra high pressure water for many years to remove paint, coatings and corrosion on marine vessels.

A water-jetted surface is preferred by most paint companies, due to its ability to remove corrosion pits and maintain the profile of the steel and to drive out impurities.

Infectious standards

Tony Quinn is also a WJA Approved Coach/Examiner with widespread experience in the Middle East. He is pleased that another trend is for managers, not just operatives, to attend his coaching events.

He says: “There is a more enlightened approach to skills development right across the region now. Managers and supervisors attending courses shows they’re aware they need to know the challenges their teams face. There is definitely a more positive mindset now.

“A key issue for us is the timescales clients need us to work to. They often need WJA events to be provided at short notice, so having examination bodies based in the region will be a great help for contractors.”

WJA Coach/Examiner Roy Dykes believes the strong focus on safety during preparations for the 2022 FIFA World Cup in Qatar has had a positive impact across other industries in the Middle East.

He says: “A decade ago, safety training was a bit of a dirty word because it took people away from their work. But now more industry leaders recognise the operational and reputational advantages.

“In the water jetting industry, contractors are also playing their part. They go from country to country in the Middle East working on different contracts and take their standards, taken from the WJA with them.

“Good standards are infectious. Once service users see the advantages of having water jetting teams that are more professional and more effective, they use them again, and everyone has to up their game.

“The WJA Blue Code is seen as a gold standard. It appears in specifications and contractors are using it as a marketing tool. Now, many insurers are requiring them in their terms. The upshot is that work sites are safer.”

Future leaders

The infection of good standards is now spreading WJA standards even farther, says WJA Approved Coach/Examiner Richard Walton. His firm is now receiving enquiries from Israel and India.

“In many cases, these enquiries are still linked with operations in the Middle East,” he explains. “For example, most jetting operatives we work with come from states in northern India, so recruitment companies may be shifting the skilling-up process back along the supply chain.

“However, this is introducing our standards into India as well. It’s a positive process. We also have engineers now coming to the UK to learn from us and take those skills back to places like Kuwait.”

He points out that developing and examining skills is an excellent way to identify future operational leaders. The process quickly reveals candidates that demonstrate a safety culture and have what it takes to become future site supervisors and operational managers.

WJA Coach/Examiners can also advise clients on technical issues, such as the optimum equipment and techniques to use for different tasks, which can enhance productivity, safety, and sustainability, and control costs.

Injury algorithm

All WJA Coach/Examiners say make the same point: safety, efficiency and effectiveness are bound together. However, when safe practice is not followed, as we have seen, the effects can be catastrophic.

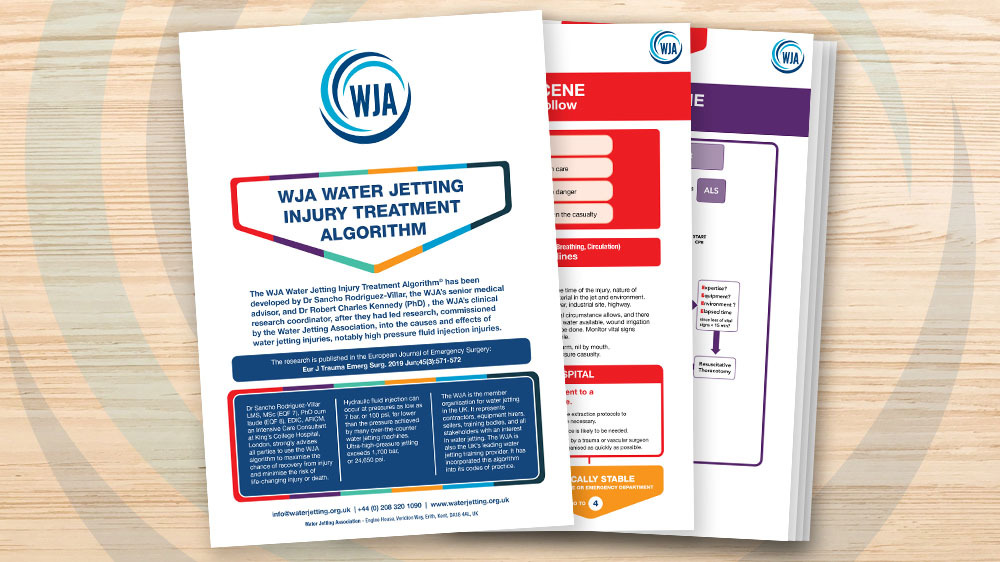

It is why a water jetting injury algorithm, developed for the WJA, is central to both our codes of practice and our coaching and examination events.

The algorithm is a step-by-step best practice guide to the treatment of injures from work site first aid through hospital care and, if needed, long-term rehabilitation.

It was developed as a result of a research commissioned by the WJA into fluid injection injuries. The resulting paper, published in the European Journal of Trauma Medicine, has been accessed more than 10,000 times in the last four years, making it the world’s most popular study on the topic.

Dr Sancho Rodriguez-Villar, a senior intensive care consultant at Kings College Hospital in London, who led the research, is the WJA’s Senior Health Advisor.

He is keen to continue his research into fluid injection injuries and can be contacted in complete confidence via the WJA website.

He is concerned that the research indicates fluid injection injuries, which can also be caused by oils, fuels, lubricants, and paints, are more common than previously thought.

He says: “Definitely, we can say [these injuries] are not as rare as we thought initially. I will say it is not as uncommon, but very likely not reported. Yet the injuries have potentially significant consequences for those who suffer them.”

No complacency

The implications of this research demonstrate there is no room for complacency. There has been significant progress in developing water jetting skills and improving safety across the Middle East.

The WJA will continue to work with stakeholders, including other water jetting bodies, to further shared aims to safeguard operatives and promote high standards, not least because this will also benefit the industries that rely so much on the technique.

About the author

John Jones is the President of the Water Jetting Association, which represents contractors, manufacturers, equipment suppliers, hire specialists, examination bodies and other stakeholders involved in the water jetting industry