Hydrodemolition – A Bearing on Bridge Maintenance

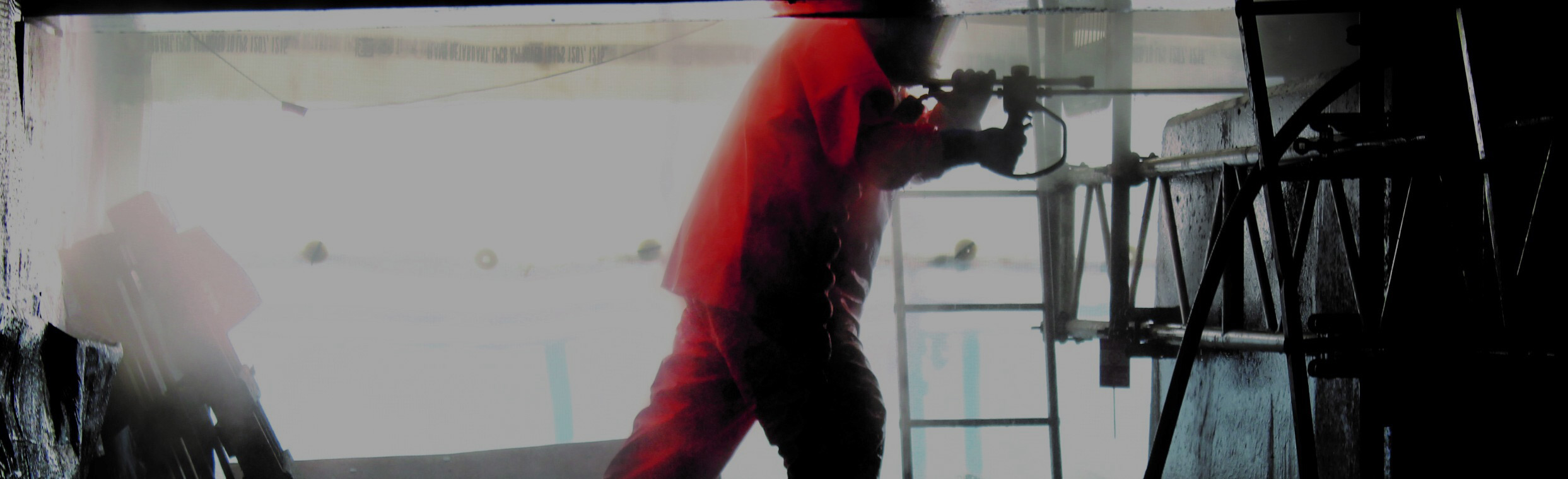

Hydrodemolition teams have supported vital maintenance on a major bridge by assisting in the removal of structural bearings so they could be replaced.

Aquaforce Concrete Services, a member of the Water Jetting Association (WJA), used high pressure jets of water to blast concrete, grout and resin from around 208 bearings under the Ouse Bridge.

The 1.6km-long bridge carries the M62 across the River Ouse between Goole and Howden in East Yorkshire.

Bridge bearings allow the structure’s sections to flex to reduce the effect of vibration caused by vehicles. Over time, they seize up, risking structural damage, so they must be replace.

In an 18-month programme, Aquaforce worked with its parent company, Freyssinet UK and Highway England’s principal contractor, A-one+, to remove the bearings so new ones could be installed.

Aquaforce General Manager Gavin Thomas said: “The project has been a great success and demonstrated our ability to work with project partners to overcome any technical challenges.

“High pressure water jetting was the fastest, safest and most precise way to release the bearings so played a significant part in the project’s success.

“All of our water jetters undergo WJA’s City & Guilds accredited training, which is augmented by our own induction and ongoing training programme, to ensure hydrodemolition systems are safe.”

WJA Director David Kennedy said: “Water jetting proved itself to be the most sustainable and least disruptive way to carry out these major repairs.”

Freyssinet teams used a system of hydraulic jacks with a maximum capacity of 8,000 tonnes to simultaneously lift bridge sections a maximum of 3mm, unloading the eight bearings beneath each girder without hindering traffic.

Aquaforce used Calder MultiJet 120 trailer-mounted pumps and handheld jetting guns operating at an average 1100 bar (17,000 PSI) at a water flowrate of 48 litres per minute, with each team using approximately 10m3 of water per shift.

The project has demonstrated the advantages of hydrodemolition in supporting maintenance tasks on concrete structures like bridges, roadways and buildings.

David Kennedy explained: “Hydrodemolition has almost none of the hand arm vibration (HAV) risks of mechanical tools, like jackhammers. Likewise, it causes no vibration damage to the structures being worked on.

“Particles released are held within water, so there is less risk of dust pollution or visibility hazards close to roads.”

Hydrodemolition can also be carried out with significant precision, and only the minimum amount of material needs to be removed, controlling costs and the need for extensive reinstatement work.

Structures that need to be retained, like rebar, are not damaged, and surfaces need little further preparation before being reworked.