WJA boosts training for improved safety and quality

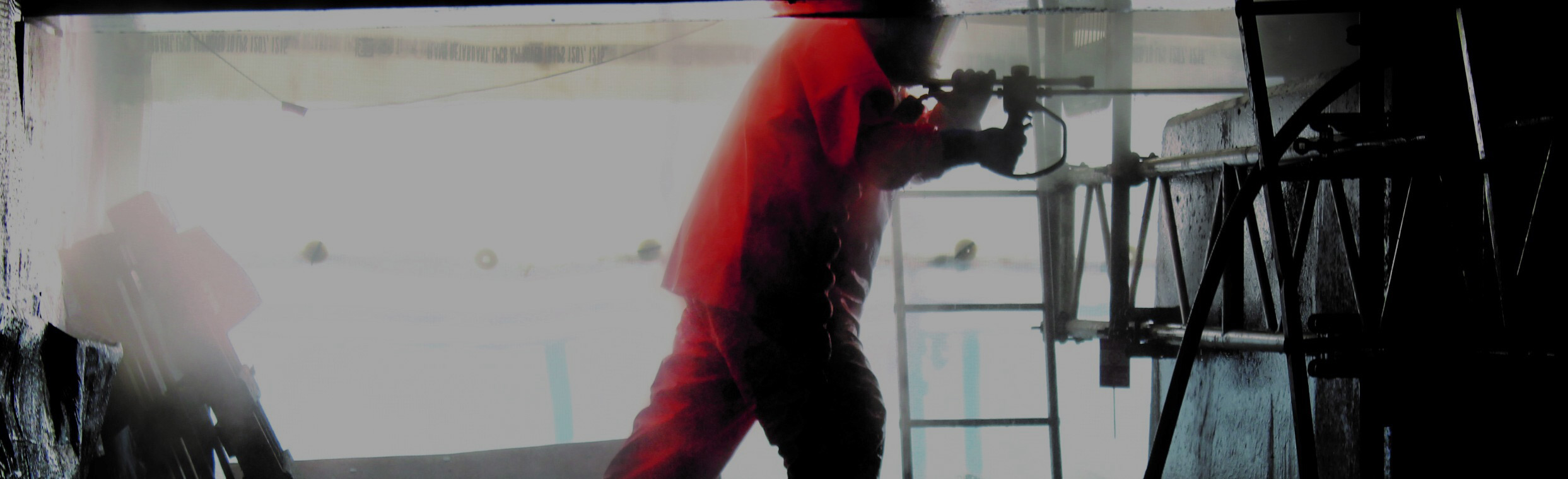

Improvements to the way training is delivered promise to enhance the quality and safety of water jetting services across all industrial sectors in the United Kingdom.

The Water Jetting Association (WJA) is strengthening its mandatory refresher training by introducing a significant element of practical tuition.

It is also upgrading the way delegates attending the City & Guilds accredited courses are examined, with digital click pads that will ensure leaning can be more rigorously tested.

The WJA is also introducing a new workbook for its Safety Awareness course that improves engagement and provides delegates with a reference guide.

Vision to improve jetting training

WJA Training and Safety Committee Chairman Darren Hamilton said: “We’re always looking to improve our training. These changes reflect the vision of our committee has to improve outcomes for delegates, contractors and their customers.

“Ultimately, by upgrading our courses in this way, making them as up-to-date as possible, with the most relevant content and learning techniques, we will improve the quality and safety of water jetting, which is our ultimate aim.”

The WJA is the membership organisation for the water jetting industry in the UK and is the largest provider of water jetting training. Courses are also delivered around the world, notably in the Middle East.

High and ultra-high pressure water jetting is a critical process for pipe and tank cleaning in the oil, gas and petrochemical industries.

It is also used for concrete hydrodemolition, surface preparation, drain and sewer cleaning, industrial cleaning, and material cutting.

To obtain their WJA cards and certificates, operatives must complete a two-stage training process.

Stronger focus on practical skills

First, they must pass the class-based one-day WJA Safety Awareness course. Then, they must complete at least one of four practical modules – Surface Preparation, Tube and Pipe Cleaning, Drain and Sewer, and Hydrodemolition.

Previously, refresher training involved passing the Safety Awareness course every three years. Now, a new refresher course has been created which is focused on practical training as well as health and safety.

Darren Hamilton said: “The new refresher process allows us to check that operatives are using the correct water jetting techniques and their skills are developing as we’d expect. We’ll also include regulation updates and technical changes introduced by the WJA.

“This is a more rounded approach designed to provide advantages for operatives, the companies they work for and their clients.”

Digital feedback for WJA instructors

The WJA is also improving learning testing by incorporating the CLiKAPAD digital audience response system within each course.

Instead of delegates being tested at the end of the course, they will use digital click pads to answer questions at set stages throughout the training. The responses are locked and the WJA instructor finds out who has passed or failed at the touch of a button at the end of the course.

“The system allows trainers to read out questions shown on screen, overcoming any potential reading difficulties operatives may have. And it provides for a more intensive and engaging learning process,” said Darren Hamilton.

“As each section is completed, training instructors see how many questions are answered correctly, giving them a chance to instantly review topics if they consider some points need reinforcing.”

Workbook guide for improved performance

The new Safety Awareness workbook, developed over two years, uses graphics and photographs to explained water jetting concepts, with sections delegates complete themselves during the course.

Once completed, operatives keep the workbook for future reference, allowing them to check what they have learned and see the progress they have made in their technical understanding.

In another development, the WJA is strengthening the verification process for those wanting to become WJA-approved training instructors.

In a new step, as well as completing a detailed form and being interviewed, they must agree to be audited as they give at least one of their first courses. As is currently the case, they must then be audited every three years.

To find out more about WJA water jetting training or to be put in touch with a WJA training instructor near you, contact the WJA today. Call: +44 20 8320 1090. Email: info@wja06.ts3.testdigital.net.