New Level 2 Water Jetting Training Will Teach and Assess

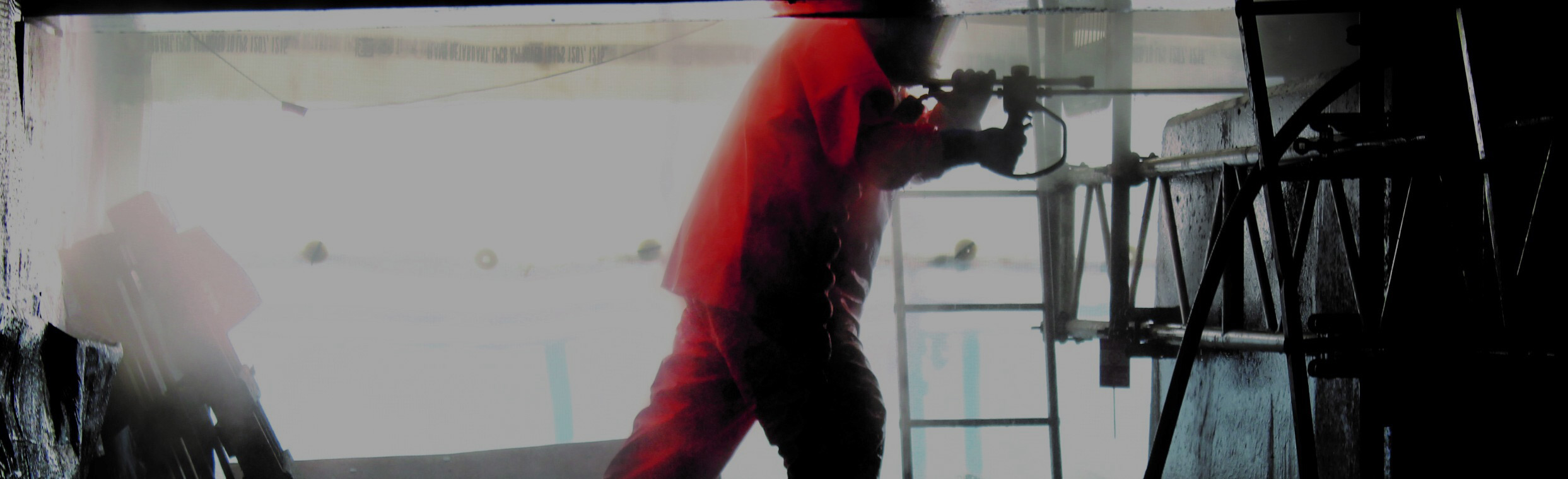

A new level 2 competent water jetting qualification will allow contractors to enhance critically important skills and support career pathways in their teams, says the Water Jetting Association.

The WJA is preparing to launch the new qualification, which is designed to give greater assurance that water jetting services, including sewer cleaning, are of a high standard.

The new qualification will overcome the limitations of a current NVQ in water jetting by combining both training and assessment, giving operatives a high quality learning experience.

WJA Director David Kennedy said: “The new WJA level 2 competent water jetting qualification will be 50% training and 50% assessment, while the current NVQ is just assessment.

“The qualification will, for the first time, introduce a proof of competence. This is good for the operative, the contractor and for the client as it gives greater assurance over service quality, productivity, and safety.

“The qualification allows water jetting operatives to hold a WJA competency card and will qualify successful candidates for a CSCS skills card.

“It adds another rung to a company’s career pathway, adding clarity to decisions about team developments and individual reward. As such, it supports the professionalisation of the water jetting industry, something we believe all responsible and forward-thinking contractors will welcome.”

The WJA says the qualification will also help address critical safety and operational issues, pointing to the outcome of the Health and Safety Executive’s (HSE) prosecution of a contractor following the most recent water jetting fatality in the UK in 2017.

The contractor, which had not been a WJA member at the time of the incident, was fined £2,000,000 and ordered to pay £30,000 in costs, after pleading guilty to breaching Section 2(1) of the Health and Safety at Work Act 1974.

A worker suffered a fatal injury while cleaning out pipework at the paint shop of a large manufacturing facility. The work involved insertion of an improvised water-jetting tool into the pipe. The tool consisted of a flexible hose with a nozzle-jet attached to the end operating at 1400 bar. During the task, the hose ejected from the pipework.

In an official statement, the HSE inspector who investigated the fatal incident urged other contractors to consult the WJA’s Blue Code of Practice for high pressure and ultra high pressure water jetting, which provides clear safety guidelines relating to manually controlled flexible lances.

David Kennedy said: “The WJA’s two codes of practice are designed specifically to prevent such incidents, which the HSE is at pains to point out. However, training and skills development is another critical component, to ensure our codes of practice are followed.

“The WJA Level 2 competent water jetting qualification will help instil both skills and attitudes that safeguard against hazardous behaviours and supports the development of positive cultures within teams. It will reduce the risk of such catastrophic events occurring.”

To qualify for the training, which will be accredited by City & Guilds, operatives must hold the one-day WJA Safety Awareness course plus the one-day Surface Preparation practical module and one other practical module.

They then undergo work-based assessment, which is expected to last a year, but longer if necessary. Operatives will complete a workbook signed off by supervisors in a process overseen by WJA-approved assessors.

If the operative passes the assessment process, they will receive a WJA competency card. It is a qualification for life. The operative will still have to follow WJA procedure by retaking the safety awareness course every three years.